Electric Power Systems

- HOME

- Electric Power Systems

- Transformers

- Furnace & Rectifier Transformers

Furnace & Rectifier Transformers

Custom-Designed

Drawing on its cutting-edge design technology and extensive experience, Kitashiba designs furnace and rectifier transformers that satisfy diverse customer needs.

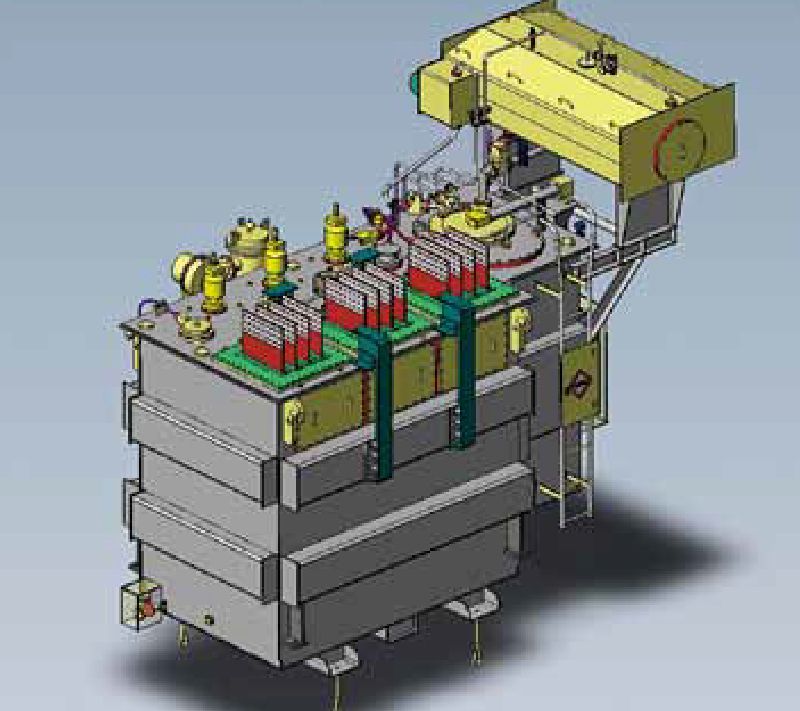

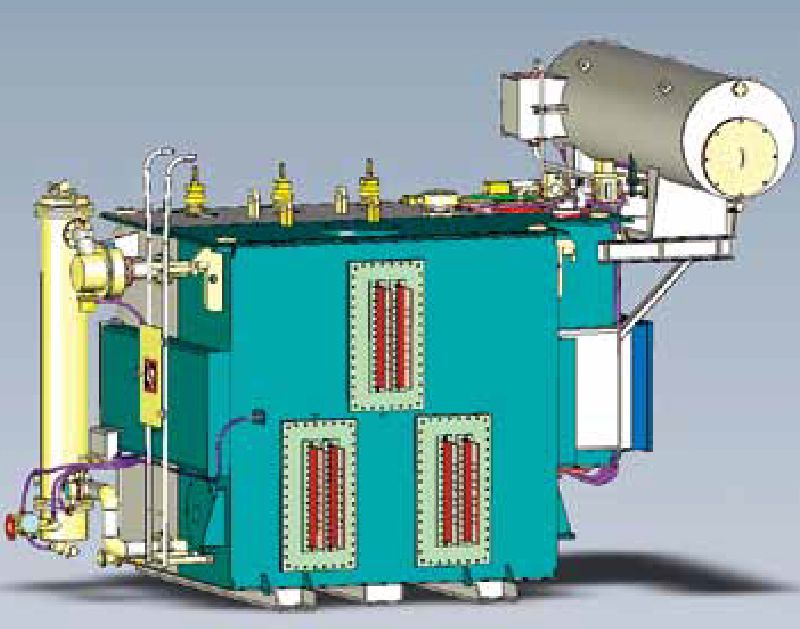

Secondary terminal arrangements and connections

Top cover mount / 3-phase in-line configuration

Open

Side tank mount / 3-phase triangular configuration

Closed

Various cooling methods

Water-cooled oil cooler + oil pump Single-tube or double-tube cooler

Forced-oil, forced-air (OFAF) transformer cooler

Oil-immersed self-cooled panel radiator

Oil-immersed forced-air-cooled panel radiator + cooling fan

Voltage control and tap changing methods

Reliability

Incorporating advanced design and manufacturing technologies, Kitashiba’s furnace and rectifier transformers provide high quality and long life. Kitashiba offers products that satisfy customers through a high level of dust control, outstanding drying technology, and stringent quality control.

Superior manufacturing technology and quality control

Manufacturing process

Core machining

High-precision machining and core stacking using core machining unit

Coil winding, and core and coil assembly

Coil winding, and core and coil assembly in dust-controlled room

Tank assembling, welding, and painting

Material processing, tank assembling, welding, and painting are performed at our own factories.

Drying core and coils

Final drying (vapor-phase drying) after assembling core and coils

Tanking and external assembly

Controlled air exposure for tanking and vacuum oil filling

Testing

Tests using automatic measurement system

Shipping

Disassembled and shipped by trailer, rail and/or boat according to transportation conditions

Simplified maintenance

Kitashiba’s furnace and rectifier transformers simplify maintenance requirements for customers. Therefore, customers can reduce the downtime due to maintenance.

Reduced maintenance items

A non-pressured sealing method is provided to prevent oil deterioration. On-load tap changers with vacuum interrupters eliminate the need for an on-load oil purifier.