Industrial Systems

- HOME

- Industrial Systems

About Kitashiba’s Industrial Systems Business

The 21st century is called "the century of the environment." Kitashiba emphasizes the importance of using limited natural resources efficiently and manufactures products that help conserve the global environment.

To contribute to the development of the formed and fabricated materials industries, Kitashiba offers highly reliable melting systems by leveraging its unique technology and extensive experience in the manufacturing of induction furnaces; cutting-edge power devices and their control technologies that help reduce environmental loads; and the energy-saving systems that connect them.

Products

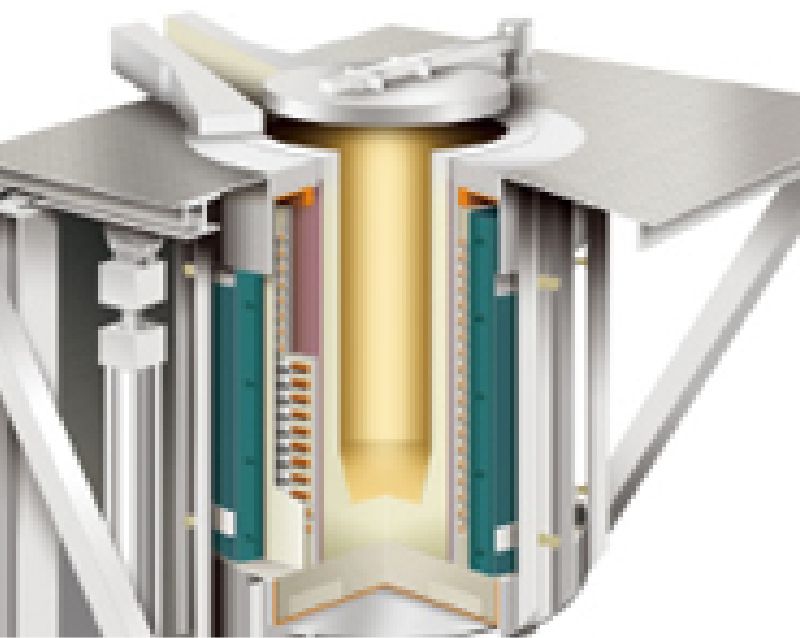

High-efficiency induction furnaces (Elesave furnaces)

Kitashiba reviewed the overall system design using electromagnetic field analysis technology to develop Elesave furnaces with improved efficiency. Drawing on extensive experience in manufacturing, Kitashiba offers highly reliable melting systems.

Small-Capacity induction furnace (micromelters)

To address the needs of laboratories and small-lot production, Kitashiba offers compact high-frequency induction furnaces that integrate a power supply unit and a furnace and thus reduce the period required for installation work.

Induction heating equipment (heaters)

Kitashiba offers various induction furnace heaters. Drawing on its extensive experience and constantly adopting new technologies, Kitashiba manufactures the hardware for steel rolling heaters under the umbrella of TMEIC Corporation.

Cooling units

Kitashiba is a general heavy machinery manufacturer with decades of experience. Drawing on its outstanding high-efficiency and high-performance technology, Kitashiba offers cooling units for the heavy electrical equipment of power generators as well as heat exchangers for steel, chemical, transportation, and other industries. Kitashiba’s highly valued and trusted products are widely used both in Japan and abroad.

Hot-Air-Circulation Drying Furnace

Kitashiba offers a drying service for the insulation and core varnish of large coils.

Equipment overview

| Highest temperature | 300℃ | |

|---|---|---|

| Drying time | The furnace temperature rises to 300°C in 50 minutes at the minimum (with no load). | |

| Maximum dimensions | External dimensions (W x D x H) | 3,700 × 4,000 × 3,850mm |

| Furnace dimensions (W x D x H) | 3,200 × 3,800 × 3,350mm | |

This drying furnace provides temperature traceability and various safety devices.

Brazing Qualifications

Kitashiba has all the brazing qualifications specified by Japanese Industrial Standards (FA-Cu, FA-S, FA-SUS, and PA-Cu).

Kitashiba offers a coil winding service for discs, pipes, and deformed coils with a diameter of 200mm to 2,500mm as well as a copper machining service using various forming, brazing, and TIG welding techniques.