Electric Power Systems

- HOME

- Electric Power Systems

- Maintenance & Service

Maintenance & Service

Electric Motors

Exposed to thermal, electrical, mechanical, and environmental stresses, electric motors deteriorate over a long period of operation. Drawing on the expertise accumulated over many years of experience, Kitashiba offers periodic diagnosis and early repair services to prevent motor failure and maintain motors in good condition. Kitashiba also offers insulation repair and coil rewinding services for failed motors.

Causes of motor deterioration

-

Thermal deterioration

A long period of operation and repeated start-stop cycles cause the coil insulation to deteriorate due to heat, reducing its mechanical and dielectric strengths.

-

Electrical deterioration

Electric motors are exposed to a starting current that is five to seven times as large as the rated current. The electromagnetic force produced by a large starting current causes the vibration of the stator coil. Repeated start-ups accelerate fatigue in the insulating layer, which sometimes results in insulation deterioration in a short period of time.

-

Mechanical deterioration

The vibration of the motor itself and external vibration cause wear and bending strain, degrading its mechanical strength. Vibration, heat, and inadequate lubrication reduce the lifetime of the bearing. In addition, a damaged bearing causes the stator and rotor cores to rub against each other, eventually leading to coil burnout.

-

Environmental deterioration

The insulation resistance of coils decreases due to the adhesion of dust, oil, and chemicals as well as condensation and moisture absorption. Decreased insulation resistance may lead to a layer short-circuit or other short-circuit faults.

Inspection & repair services

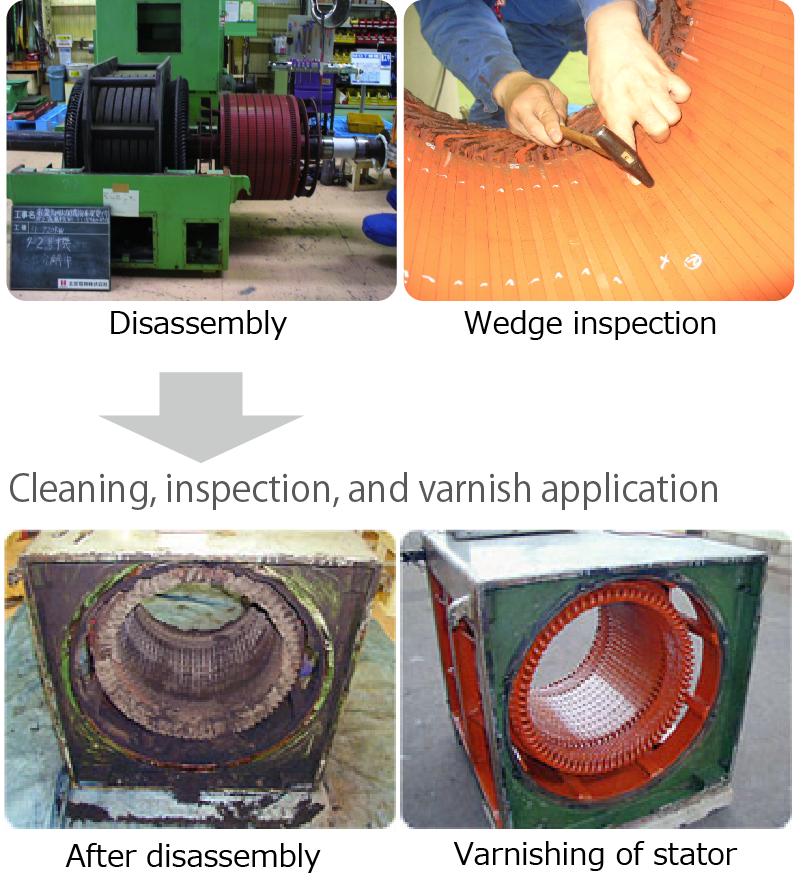

Overhaul inspection

Generally, electric motors undergo an overhaul inspection. Motors with low insulation resistance are disassembled to clean and dry their components.

Stains on the coils are carefully removed. After the coils are dried, they are varnished to improve their insulation characteristics.

Insulation diagnosis

High-voltage motors and generators undergo insulation tests.

Test items

- Coil resistance measurement

- DC absorption test

- Dielectric loss tangent test (tanδ test)

- Insulation resistance test

- DC test

- Partial discharge test (corona test)

A point rating method based on the results of the above tests is used for the diagnosis of insulation.

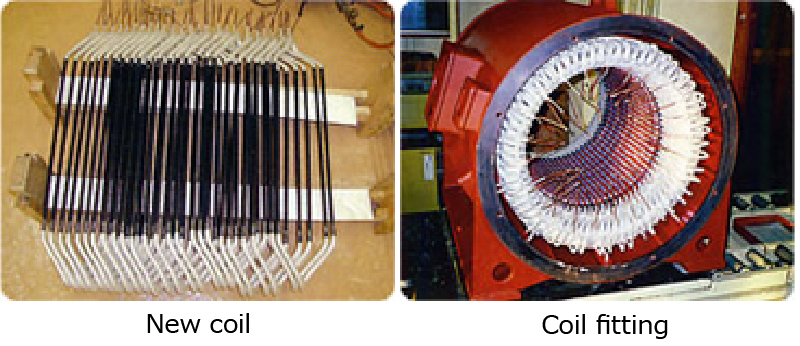

Coil rewinding

A coil must be rewound if it is burned out or has any damage to the insulation. Drawing on the expertise accumulated over many years of experience, Kitashiba rewinds the coil to restore it to mint condition.

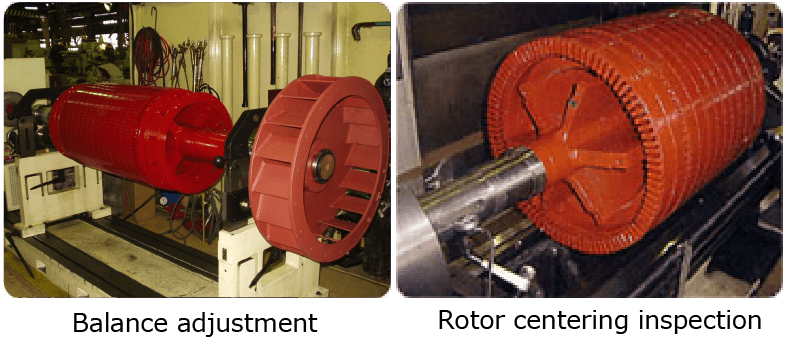

Tests and inspections

Kitashiba possesses various test and inspection systems. Motors and generators can be tested at both Kitashiba’s factory and customers’ sites.

Wind Power Generators

In Japan, wind power generators are subject to frequent start-stop cycles due to constantly changing wind directions. Therefore, wind power generators are exposed to greater thermal, electrical, mechanical, and environmental stresses than other types of generators. Drawing on the expertise accumulated over many years of experience, Kitashiba offers periodic diagnosis and early repair services to reduce downtime.

Stator rewinding

Inspection of squirrel-cage stator winding and repair of worn shaft